With 2020 in the rearview mirror, summer upon us, and varying covid restrictions easing, 2021 is shaping up to be more “normal”. For this, the DIS team is grateful.

The DIS team continues to branch out to new areas but our march persists in familiar territory as well. As readers may recall, we completed some exciting work in the State of Missouri in 2019, which I summarized in earlier articles: "The "Quilt Map" Returns", and "Missouri Commodity Flow and Infrastructure Social Media Campaign". Not long after using our Dynamic Flow Analysis™ methodology to complete work in Missouri for farm commodities (corn, soybeans, grain sorghum, and wheat), we were asked to conduct a commodity flow study for biodiesel in Missouri. And, more recently, a forthcoming report for the Illinois Farm Bureau used our Dynamic Flow Analysis™ methodology to look at how the flow of cattle and hogs to market could influence the expansion of local meat processing in Illinois.

We wanted to share how we used this methodology in the commodity flow study we conducted for biodiesel in Missouri, and how it is being used in Illinois in regard to the potential expansion of local meat processing.

Increased Biodiesel Use in Missouri

This project evaluated the impacts of a new fuel standard policy in Missouri in comparison with the current situation. The project evaluated these impacts from different interrelated perspectives:

- Diesel and biodiesel consumption in the state

- Missouri out-of-state biodiesel shipments

- Biodiesel production

- Soybeans and soybean oil usage

- Number of processors

- Number of Missouri biodiesel producers

- Impact on current biodiesel and soybean oil production capacity

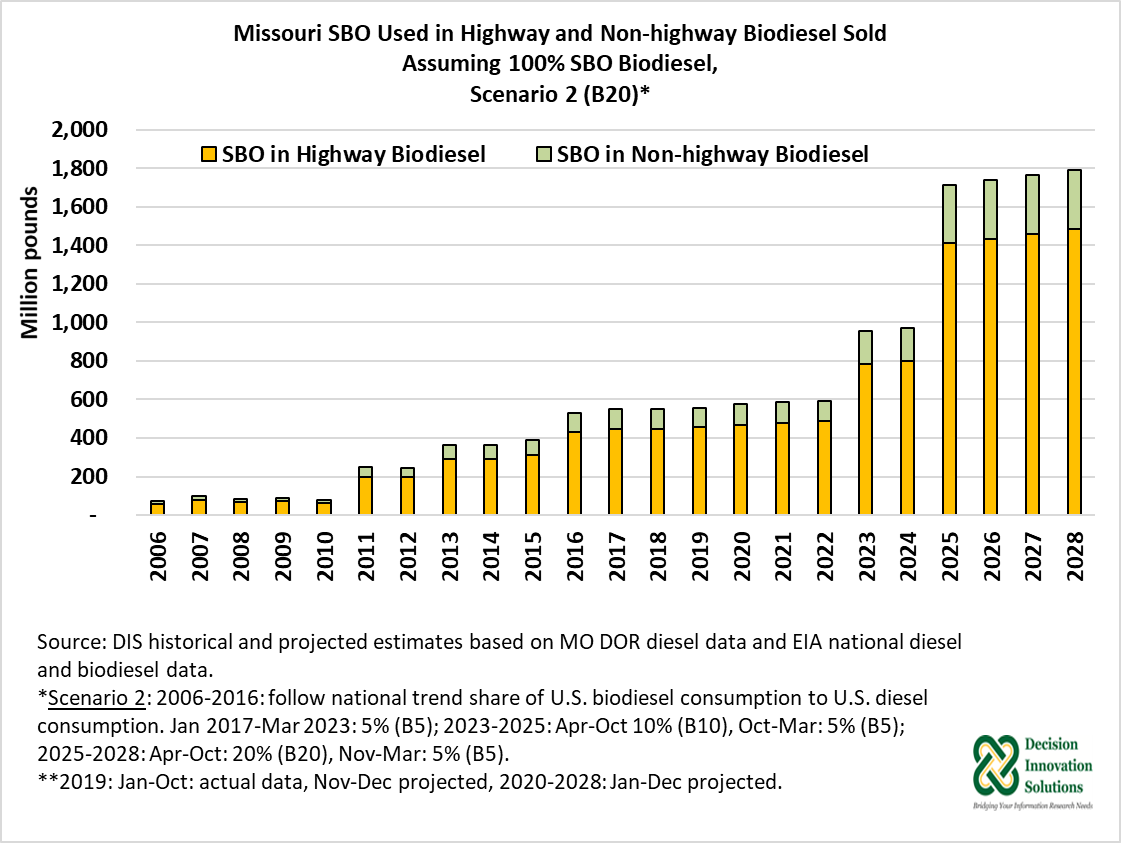

Figure 1. Missouri SBO Used in Highway and Non-Highway Biodiesel Sold, Assuming 100% SBO Biodiesel, Scenario 2 (B20)

Under the new biodiesel fuel policy, the industry is expected to grow, hence the corresponding additional economic activity from increased soybean production, soybean processing, and the construction of a new plant was estimated.

In addition to evaluating these core components, this project included a Dynamic Flow Analysis™ to model the flow of biodiesel from soy-based biodiesel production facilities in Missouri and selected contiguous states. View the full report here.

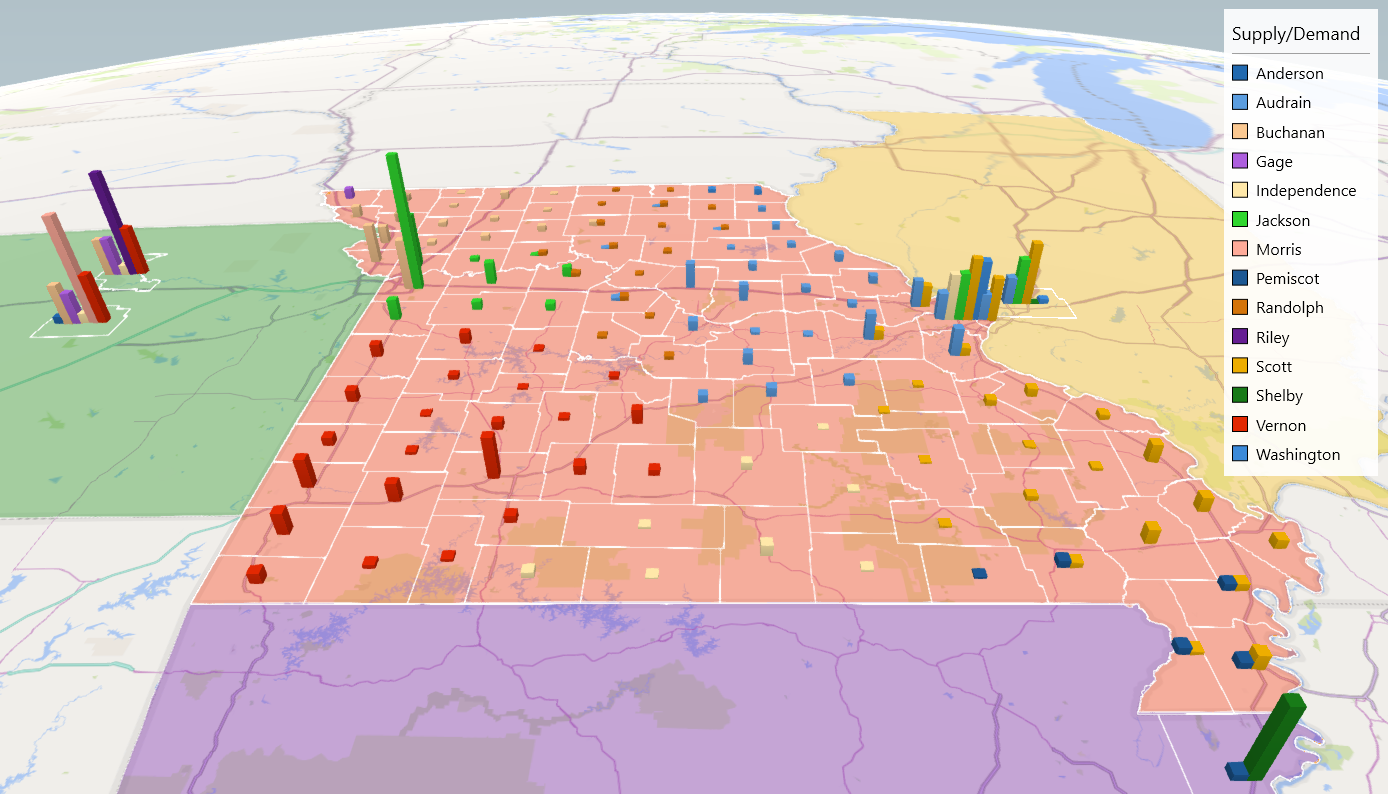

An example of the output of the Dynamic Flow Analysis is shown below:

2028 Scenario 2B Regional Flow analysis with 50 million gallons in Scott Co., MO

The 2028 flow analysis adds the unused capacity from biodiesel plants in the abutting CRDs, 38 million gallons of supply from outside of the region – used to partially satisfy western out-of-state demand –, and 50 million gallons of supply in Scott County, Missouri. With the addition of 50 million gallons of biodiesel production in Scott County, Missouri, and substantially increased use in the Kansas City and St. Louis metropolitan areas, the flow patterns change. Much more of the Buchanan and Jackson County biodiesel production is used within the Kansas City and St. Joseph metropolitan areas. Scott county biodiesel would satisfy biodiesel needs in a greater portion of the Ozarks, and will also become a significant supply point for the St. Louis metropolitan area (35%) and eastern out-of-state shipments (44%). Southern out-of-state shipments would likely be satisfied by the Shelby County, TN biodiesel facility (92%). On the other hand, western out-of-state shipments would be satisfied by shipments from Kansas biodiesel facilities (46%), Buchanan Co., MO (16%), Gage Co., NE (14%), Independence Co., AR (4%), and Vernon Co., MO (20%).

Figure 2. Regional Biodiesel Flow Analysis 2028, with Scott Co., MO Biodiesel Plant

Local Meat Processor Expansion in Illinois

Another recent application of the Dynamic Flow Analysis™ methodology examined two important aspects of Illinois agriculture: 1) the economic impact of a new or refurbished local meat processor; and 2) the current draw areas for hogs and cattle for current livestock slaughter and processing in Illinois and surrounding states. The intent of completing these two components of research was to identify potential opportunities in Illinois that would benefit from an expansion in local meat processing.

As we continue to refine and expand our Dynamic Flow Analysis™ methodology, other exciting opportunities are opening up for the team. And, generally speaking, without a great, diverse team intent on learning and applying new skills, DIS would have struggled throughout the last 18 months. Adaptability, industriousness, persistence, and innovativeness have allowed the team to thrive in these unique circumstances; we are excited to work with past, existing, and new clients for the rest of 2021 and beyond.