We hear a lot in the news about the positive economic impact on a community when a company like Prestage decides to locate a pork processing plant in the area. While the financial benefits are very important to the community and to the people who will have an opportunity to improve their life, there are some other benefits to consider.

While Iowa has a high population of hogs being fed for the market, many of the market ready hogs are being transported to processing facilities in other states or, at the very least, long distances to the nearest processing facility.

Locating a processing plant near a large population of animals reduces the stress during transportation and significantly reduces the overall impact of transportation on the animals and on the environment. As transportation distances are reduced the overall efficiency of that component increases. Animals need less space during the trip so head counts can be increased. Also, increasing load weights has little effect on modern diesel engines so miles per gallon stays about the same and total consumption goes down which reduces the carbon footprint of the transportation segment.

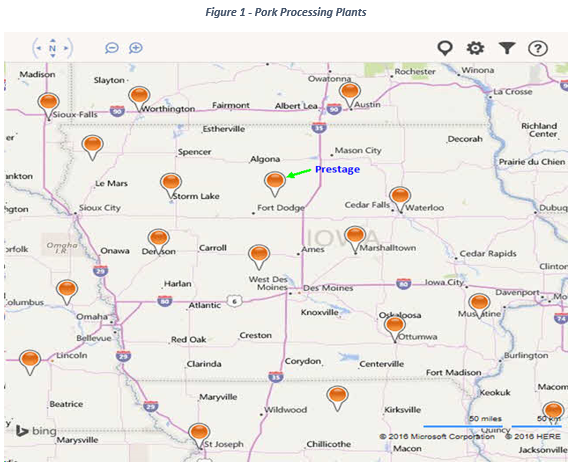

I created the map in Figure 1 by identifying all of the major pork processing plants within a 5-hour drive of the proposed location near Eagle Grove. The proposed Prestage plant is identified with a green arrow and the label “Prestage” just under Mason City.

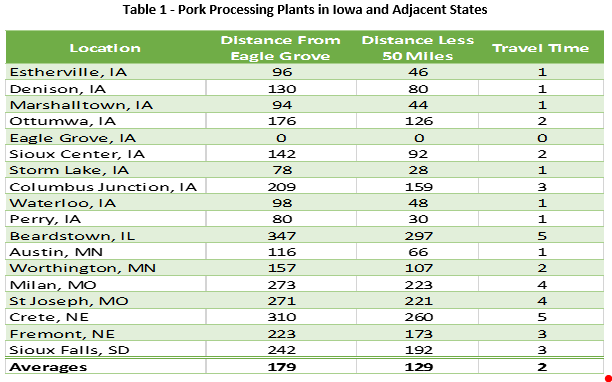

Using the proposed Prestage pork plant near Eagle Grove as home base, I created Table 1 which lists the pork processing plants shown in Figure 1. Using Quick Maps, I calculated the distance to all of the plants in the list. I subtracted 50 miles from that distance to recognize that all shipping locations are not at home base. I calculated average travel time by dividing the miles by 55 mph which should accommodate some stops and wait time.

The basic premise here is that travel time and distances are reduced by locating the Prestage Pork Processing plant near the hog production sites. This results in less fuel consumed and less stress on the animals. Studies have shown that reducing stress on slaughter weight hogs improves the quality of the meat and it is always good to reduce stress on the animals.

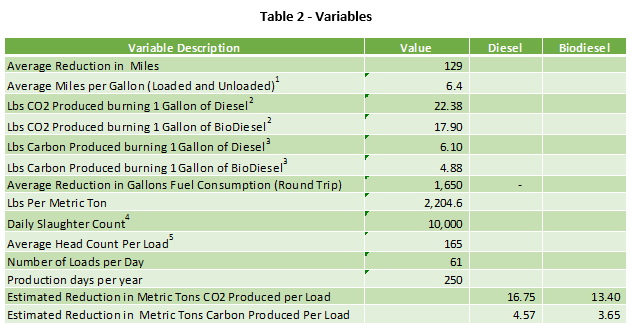

While the use of biodiesel is growing, I calculated the results per trip for both diesel and biodiesel. The actual benefits are probably somewhere in the middle of the two calculated values.

Whenever you attempt this kind of study the variables used are always a concern. The following Table 2 lists the variables used in this discussion:

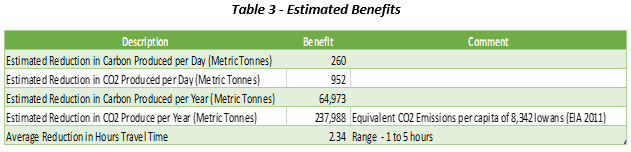

The following Table 3 summarizes the daily and yearly overall benefits to the planet and to the animals during transport.

While this exercise is based on averages, it is reasonable to assume that the overall reduction in the annual production of CO2 for the transportation segment of this operation is equal to the annual CO2 production attributed to at least 8,300 Iowans. Producing higher quality meat with less stress on the animals is an added bonus.

Sources:

1EIA Annual Energy Review http://www.eia.gov/totalenergy/data/annual/showtext.cfm?t=ptb0208

2 EIA How much carbon dioxide is produced by burning gasoline and diesel fuel? http://www.eia.gov/tools/faqs/faq.cfm?id=307&t=11

3 Why do C02 emissions weigh more than the original fuel? https://www.eia.gov/tools/faqs/faq.cfm?id=82&t=11

4 Company press releases

5 Reducing Pig Transport Losses – Fitzgerald and Stalder, Iowa State University 6/15/2009 http://nationalhogfarmer.com/behavior-welfare/0615-reducing-transport-pig-losses